If your car's brake pedal has been feeling spongy or unresponsive recently, then you might be dealing with air trapped in your brake lines. While it is fairly normal for air to occasionally find its way into your brake line, without regular brake maintenance it can result in poor brake response and increased safety concerns.

Traditionally, the process of brake bleeding has been used to eliminate this air. However, this method can be time-consuming, require the help of a professional, and necessitates the use of specialized parts such as clear plastic tubing, vacuum pumps, bleeder valve adapters, and more. So, you must be wondering, can I get air out of the brake lines without bleeding? The simple answer is, yes.

In this blog post, we'll walk you through a comprehensive guide on how to get air out of your brake lines without resorting to traditional brake bleeding. This guide will not only help you understand your car's brake system better but will also provide you with a step-by-step process to keep your brake lines air-free and your car safe.

Understanding Your Car's Brake System

If this is your first time fixing your brakes at home, it can really help to have a good understanding of your car's brake system. The brake system is one of the most critical safety systems in your car, and that's why it's important to ensure each component is functioning at its best.

Key Components of a Brake System

Brake Lines & Brake Hoses: These are the essential conduits that transfer the brake fluid from the master cylinder to the brakes at each wheel. Their core purpose is to deliver enough force to stop your car when you hit the brake pedal.

Brake Fluid: This is a special type of hydraulic fluid specifically designed to withstand the high pressures and temperatures in the brake system. Brake fluid transfers the force of you pushing the brake pedal to the wheel cylinder.

Brake Master Cylinder: This is what generates hydraulic pressure in the brake system, which is then transferred through the brake lines and used to push the brake pads against the brake rotors.

Brake Pedal: The brake system's point of contact with the driver. When you press the brake pedal, it acts upon the master cylinder using a lever system, which subsequently pressurizes the brake fluid causing the car to slow down or stop.

Now, you might be wondering, how does air get into these hydraulic brakes? Air can find its way into the system through numerous means such as through a brake line leak, replacing a component, or even during a brake fluid top-up. When air gets entrapped in the brake lines, it forms air bubbles. Unlike brake fluid, air can be compressed. This means that when you press down on the brake pedal, some of the pressure will be consumed compressing the air bubble instead of applying force to the brake pads. Consequently, this can lead to a less responsive or 'spongy' brake pedal, negatively affecting braking performance

Conventional Brake Bleeding and Its Limitations

Brake bleeding is the conventional method used to rid brake lines of any trapped air. This process involves loosening the bleeder screws at each wheel cylinder or brake caliper to release brake fluid and air into a catch container. You can then refill your brake line with new fluid through the master cylinder reservoir. Note that some will attempt to refill using the old fluid they just drained; however, we strongly recommend the use of fresh fluid because brake fluid is hygroscopic and therefore absorbs water over time, increasing the likelihood of corroding your brake lines.

This being said, the traditional brake bleeding process comes with its own set of challenges and limitations. Some of the significant issues include:

- Need for Additional Equipment or Help: Brake bleeding often requires a bleed kit which involves more than just a simple set of tools. You might need a pressure bleeder, vacuum bleeder, or additional help to press the brake pedal while you open and close the bleeder screws.

- Possibility of Introducing More Air: If not done properly, each time you loosen the bleeder screw, there's a chance that you might inadvertently introduce more air into the system.

- Messy: Traditional brake bleeding can be quite a messy process, especially for those who do not have experience with bleeding brakes.

At RPUI, we understand that these complications can make brake bleeding quite a daunting task for those not well-versed in car mechanics and enthusiasts who enjoy the art of classic car restoration but aren't professional mechanics by trade. After all, while our passion for cars may unite us, we acknowledge there's a whole spectrum of car enthusiasts.

In the next section, we're going to guide you towards an alternative method to get that trapped air out of your brake lines, without the need for bleeding. This method will save you time, minimize potential mess, and most importantly, ensure that your car’s braking system is functioning effectively and safely.

Step-by-Step Guide on How to Get Air Out of Brake Lines Without Bleeding

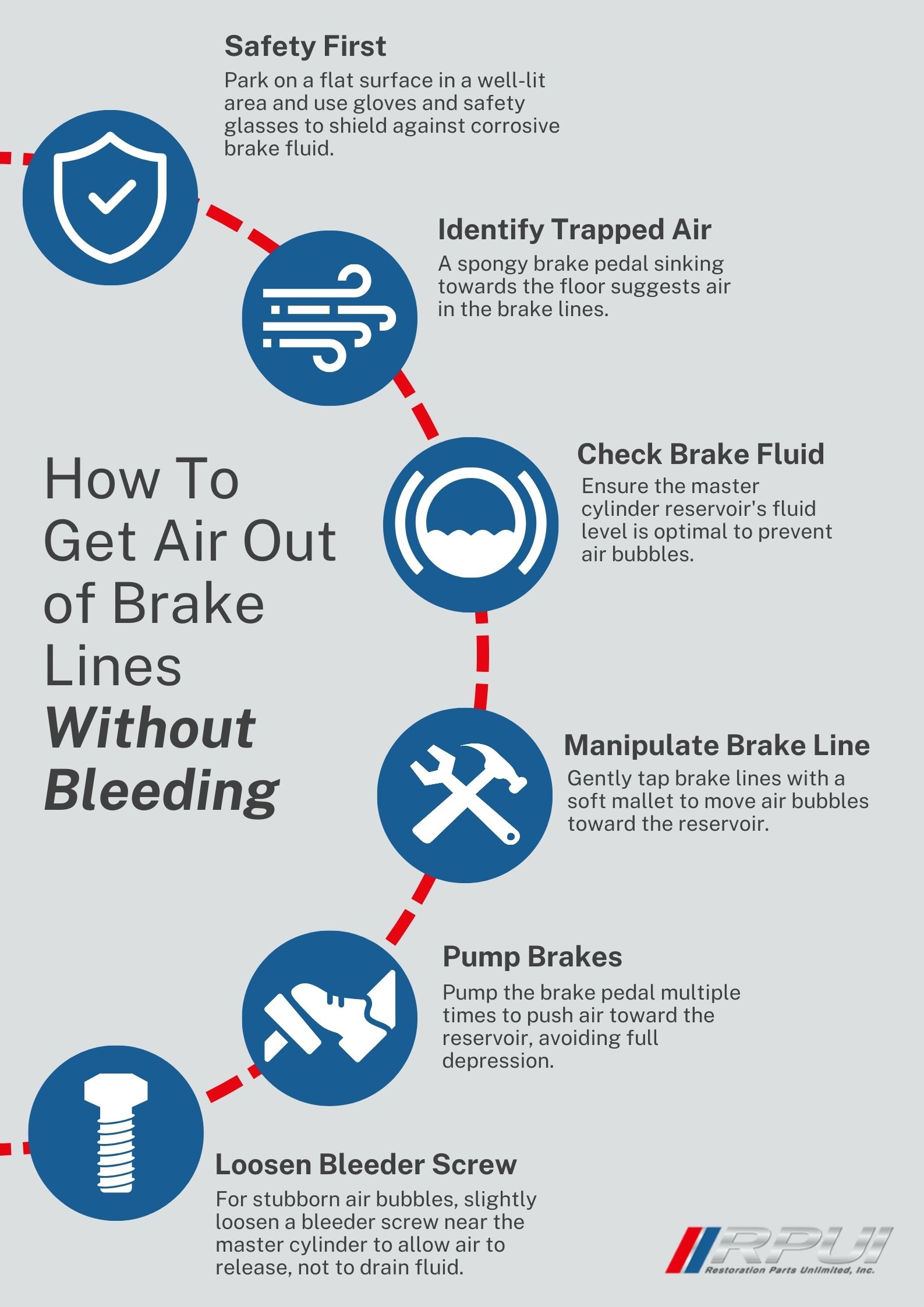

Having equipped ourselves with an understanding of the brake system and acknowledged the limitations of traditional brake bleeding, let's delve into the process of extracting air from brake lines without bleeding. Here's a step-by-step guide:

Step 1: Safety Precautions

Park your car on a flat surface and ensure that your working area is well-lit. Use safety equipment like gloves and safety glasses to protect yourself from brake fluid, which can be corrosive.

Step 2: Identify the Trapped Air

Press your brake pedal and hold it down for a few seconds. If the pedal feels spongy and gradually sinks towards the floor, this is a good indicator that there might be air in your brake lines.

Step 3: Inspect the Brake Fluid Reservoir

Pop the hood and locate your master cylinder reservoir. This is where brake fluid is stored. Check the fluid level to ensure it's at the optimal point and not under or over-filled, as this can lead to air bubbles getting into the brake line.

Step 4: Manipulate the Brake Line

Gently tap on the brake lines to dislodge any air bubbles and aid them toward the master cylinder reservoir. You can use a soft rubber mallet for this to avoid damaging your OEM or stainless steel brake lines.

Step 5: Pump the Brake Pedal

Next, go back into your car and pump the brake pedal numerous times. This process should push the air bubble trapped in the line back toward the master cylinder reservoir. Remember not to push the pedal all the way down as doing this could potentially extend the master cylinder beyond its usual limit and introduce more air into the system.

Step 6: Pro Tip - Using a Bleeder Screw

If the air bubble is stubborn and pumping the brake pedal didn’t work, consider using a bleeder screw. While we aim to avoid traditional bleeding procedures, sometimes slightly loosening a bleeder screw near the master cylinder can provide the needed path of least resistance for air to be pushed out. The aim is to do this without draining out any brake fluid which would essentially turn this into a brake bleeder method.

Step 7: Recheck and Repeat if Necessary

Recheck your brake pedal for firmness. If your pedal still feels spongy or sinks down, repeat the previous steps again.

As you can tell from these simple steps, removing air from brake lines without bleeding is less cumbersome, needs no additional person to assist, and causes minimal mess. All you need is patience and a few basic tools. Moreover, you can do it as often as you sense the need without fear of negative impacts.

Ensuring Long-Term Maintenance of Your Brake System

Maintaining the brake system of your classic vehicle is essential for its long-term performance and safety. One aspect of this is knowing how to get the air out of the brake lines without bleeding. However, it's equally crucial to understand preventative measures to stop air from entering those lines again.

Regular Fluid Checks

The fluid in your master cylinder reservoir should always be at its optimal level — neither too high nor too low. By inspecting the brake fluid reservoir regularly, you can prevent air bubbles from making their way into the brake lines.

Fresh Brake Fluid

With time, brake fluid can absorb moisture from its surroundings. This can diminish its efficacy and increase the chances of air bubble formation. To combat this, ensure that you replace the old brake fluid with new brake fluid every two years, or follow your vehicle manufacturer's recommendation.

Check for Leaks

By consistently examining your vehicle for potential brake fluid leaks, you can catch issues early on. Pay special attention to the master cylinder, wheel cylinders, brake lines, and bleeder screws. Even the slightest leak can pave the way for air to get into the brake system if left unchecked.

Periodically Inspect Brake Lines

Regularly inspect the brake lines and calipers for signs of wear and damage. If you notice any aging or damage, it's a good idea to replace those parts. Remember, using high-quality replacement parts, like the ones we offer at RPUI, can significantly enhance the durability and efficiency of your brake system.

RPUI: The Right Stuff

All told, while mastering the intricacies of brake maintenance is vital, equipping your vehicle with only the best brake components is equally crucial. Don't compromise on the health and longevity of your classic vehicle. Choose The Right Stuff for dependable, high-quality brake components, disc brake conversions, pre-bent tubing, and cables & hoses. Our products promise both durability and peak performance. Trust in our commitment to excellence, and let us be your go-to partner in ensuring your vehicle remains a timeless treasure on the road.